Our 3D Inspection experience across various industries with a wide range of clients and different requirements served us a great deal in assessing the quality of our internal manufacturing processes.

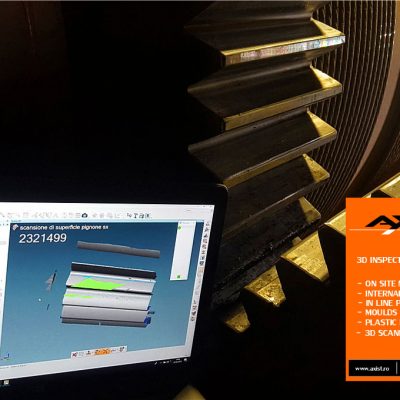

Along with the use of standard manufacturing control instruments dedicated to quality checks, we also use specific 3D inspection instruments and software to check our final products for dimensional deviations.

Based on the clients request

we can:

Individually inspect the manufactured parts and issues

unique 3D control reports ;

Assist in leveling and aligning the parts

to be welded or otherwise assembled;

3D inspect and adjust the assembled final jig and fixture;

Perform the periodical 3D control audit for older tooling;

For the 3D Inspection Services we use poly articulated arms and laser trackers from top producers:

Faro Platinum 2.4m range – 2 units;

Faro Prime 3.0m range – 1 unit;

API T3 Laser Tracker – 1 unit;

Faro Xi Laser Tracker – 1 unit;

If you are looking for on site 3D Inspection Services, give us a call or write us a message!

Coming from a 3D inspection services company, our technicians have gained their experience in multiple applications spread across many industries.

The software applications we are experienced with are Metrolog, PolyWorks, SpatialAnalyzer.

Along the years we have used almost the entire range of 3D measurement instruments from Leica, Faro, API, Romer.

Just 5 small steps to get your product?

Fast analysis of 3D and 2D documentation

Fast email

quotation

Once order received, we start the manufacturing

Periodic updates on the job status

Assembly

and shipping